Call 811 - Protect yourself and the public

Call 811 before you dig. Have you seen those signs? 811 is a nationwide number for use by anyone wanting to dig into the ground. The reminder to call 811 is posted because there is an incredible amount of infrastructure buried underground. Imagine 36” diameter steel pipes filled with pressurized natural gas; pipes filled with gasoline and diesel; high voltage electrical cables; and numerous fiber-optic and telephone cables. This infrastructure is vital to keep us all warm, moving, making things and communicating. Our society cannot run without this infrastructure. When a cable or a pipe is cut the impact is felt immediately, and the result can be an inconvenience or worse. Sometimes people are hurt or killed.

It is very important to call 811 before any excavation project begins. The project might be planting a tree or building a fence. No matter, it is very important to call 811 and request locates for utilities that might be in the path of the project. For contractors like Electric Conduit Construction (ECC), calling 811 is an everyday occurrence.

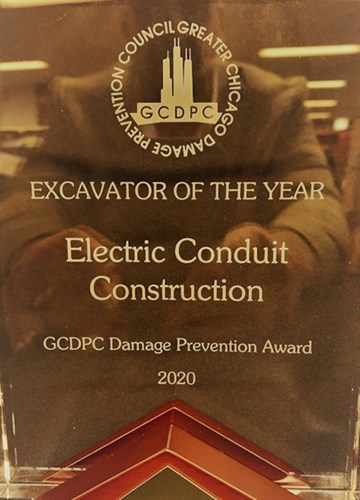

ECC installs telecommunication and electrical infrastructure. Typically, these cables are buried, in conduit, by trenching or directional drilling. ECC recently was awarded Contractor of the Year by the Greater Chicago Damage Prevention Council. This coveted award represents the Council’s recognition of a contractor’s excellence at preventing and avoiding utility damage during their construction projects.

To grasp the scale of ECC’s work consider that in 2018 ECC filed 67,804 tickets with 811. In 2019 the number was 101,862 tickets. In 2019 ECC had zero, at fault, strikes. This is an incredible accomplishment. The story behind these facts and how this record was achieved is worth telling in the hope that more contractors can avoid damaging utilities during excavation and directional drilling.

In 2019 ECC fielded over 60 crews per day. This included:

- Fiber Splicing

- Fiber/Innerduct Placement

- DAS/Node

- Pole/Foundation

- Open Cut Trench

- Directional Bore

- Vacuum Excavation

The potential for a utility strike exists in the work that these crews perform each day. The responsibility for avoiding strikes is the responsibility of every member of these crews. ECC instills this idea with training and reinforces it through management. Avoidance of utility strikes is a safety issue. It is a quality issue, and it is a productivity issue. The safety training each employee receives begins with orientation and is augmented with daily toolbox talks, monthly safety stand-downs, field supervision and peer to peer mentoring. This single, focused goal of avoiding utility strikes occupies a top-of-mind position with all our employees.

Utility strikes directly affect quality and productivity. Every strike becomes a delay for the crew. Damage must be documented, investigated and reported. A utility strike also means that the line of lay must be altered. In the case of a drill the stem must be withdrawn and a new path found. All of this takes time, costs money and delays projects. Good training on how to avoid strikes is the best way to maintain quality and keep a project moving.

Experienced foremen play an integral part in avoiding utility strikes. Their knowledge of utility placement, and interpretation of locate marks, enables them to spot anomalies and ask questions about what the lines on the ground are depicting. They may call for more hydro-excavation to extend a slot trench or probe deeper if the utility is not found. Their diligence in exploring for and finding each utility is not lost on the crew members. As awareness deepens the entire crew uses this knowledge to look critically at a job site, evaluate the locate marks and look for any irregularity that might suggest an unmarked utility or a utility that has not been revealed.

Our crews utilize STAR – (Stop – Think – Act – Review). This helps avoid costly errors, maintain productivity and keep the public safe. Our customers get a quality project, completed on time.

There are times when a simple idea is the best one. This is indeed true with utility damage prevention. When sixty crews, and over 300 employees are all striving to positively identify every utility before drilling or sinking an excavator’s bucket, then they are creating a clear path through the work zone. This clear path leads to safety, productivity and quality. This team approach and adherence to goals is what distinguishes Electric Conduit Construction as a premier utility contractor. We would not achieve this without the diligence of our employees and we thank everyone of them.